Add in a bunch of tooling (I believe the QCGB was an option) and you might get to most of it (mecury zehpher for example was 4350 US at 1.15 exchange = 5000 CDN). With the exchange rate at the time, that's about 2650 CDN. To check up on it, a quick search found a mention of a Super 7 in 1979 being 1010 pounds, with just a chuck. I can the myford, and although I get the OP was about an ML7, my comments were about the super 7 which has a significant value difference from the ML7įor sure some conjecture is involved, but the underlying thought comes from imprints left by old Model Engineer mags. Was the price for the SB just the lathe, or a total with all kinds of tooling? There was no intent by me to compare the two, i've not owned a SB so I can't comment on its fit and finish. Please correct me if my calculations are incorrect. For an ML7 to sell for 4K seems illogical. Today used machines in the SB9A model can be had for 1-2K. If the original price was a reflection of their quality then the South Bend 9A must be a much better machine than the Myford ML7. My conclusion would be that in their day of manufacture the South Bend 9A was a much more expensive lathe than the Myford ML7. There is mention on a Myford lathe forum where someone says they bought their Myford ML7 new in 1968 for 120 BP including accessoriesĪccording to a website with historical exchange rates that translates to about $360 CAD in 1968.Īccording to another website listing historical car prices a cheap Renault 4 in 1968 cost about 400BP in England. ( Can include a copy if anyone doesn't believe me)Īccording to Google the average car in Canada at the time cost about $2,750 If we exclude the import duties for a fairer comparison the price was $1232 CAD.

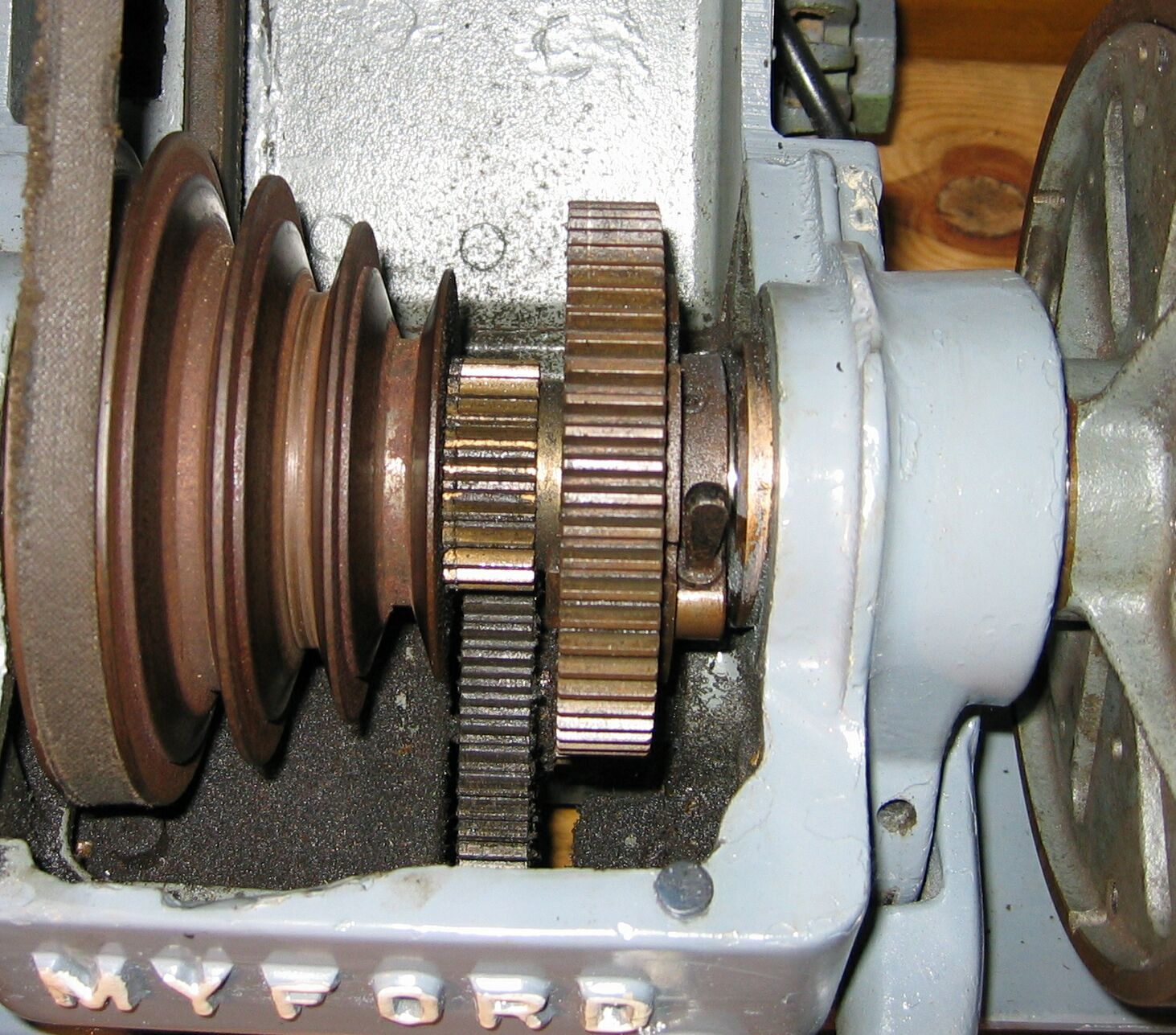

It was purchased in Toronto for $1590 CAD including a few accessories but not including taxes. I have the original purchase papers for my South Bend 9A from 1967. So I went on a search for a factual comparison. This sounds like a very interesting perspective but strikes me as conjecture more than fact with respect to Myford lathes specifically. Next up is the tailstock, lap the bore, hard chrome and grind the quill then scrape for alignment.just as soon as I finish the Schaublin 70 project! just for kicks, here's some shots of the scraped bed of mine.and this one does have a QCGB! As a manufacturer, Holbrook is up there with Pacemaker, Monarch, DSG etc and this was their baby lathe. The only reservation I'd have on Super 7 is the box ways, maybe its not an issue but I like inverted V's.Ī fantastic lathe about the same size with V ways is Holbrook B8 which is a current project of mine. If you had $100MM in the bank, who cares if its 4, 6 or 15 thousand? Most of us want to pay as little as possible, but you only go around once so sometimes its better to get what you want. Since we're sort of rambling (or at least I am), I guess price/value recieved is also relative. I think the fit and finish of them is quality worthy of the price.

Many criticize their pricing as the result of unwarranted fandom, but I disagree. They were built to a different expectation. That's what it costs to build quality and they did not disappoint. Myford's had their heyday in an area when a nice little lathe costs the better part of what a new car did. But man, are they ever nice! They leave most others wanting, and that's what it costs today to build exception quality. Price out Schaublin 70 stuff for a sticker shock.like the old divorce joke, "why does it cost so much? Because its worth it!" If you've got 30,000 - 45,000 you can go buy a new Schaublin 70 or Levin lathe - lathes that you can basically carry under your arm. I mostly agree with you, if it was Super 7. This from a man who has no less than twelve sewing machines, and none of them newer than 1970! I know, I’m sure that doesn’t make sense to a lot of people but for some there may be more in the mix than just the hard specifications.

There are few others with those qualities within reach so it fills a niche market in some respects. “How can a machine that small with no this or that cost that much? when that’s exactly why it can cost that much. I think there’s an odd kind of wave-action where small machines all of a sudden start costing more than larger (and usually more capable) counterparts and it’s hard for people to get their heads around that. And, no electronics to crap out in five years, no boards to fry, no plastic knobs to break. Why? I’m not sure really, but when I look at that machine I see a good quality machine capable of nice precision in a size that is very manageable for a basement shop. And I can say that honestly because there was a gorgeous, new-in-crate one that came up here a few years ago for 6 grand and I did consider that one!

0 kommentar(er)

0 kommentar(er)